Material science sits at the crossroads of physics, chemistry, and engineering. It’s the field that transforms raw elements into the advanced materials that power our modern world. From the smartphone in your pocket to the aircraft soaring overhead, materials scientists and engineers have crafted innovations that reshape entire industries.

Patents play a crucial role in this transformation. They protect groundbreaking discoveries while encouraging further innovation. This incentives development of new material products which can benefit humanity as a whole.

This exploration reveals ten patents that have made their mark on human progress. These breakthroughs span decades of research, covering everything from revolutionary polymers to game-changing semiconductors. The field encompasses many materials, including nanomaterials, biomaterials, ceramics, and energy materials, highlighting its vast diversity.

Introduction to Materials Science

Materials science is an interdisciplinary field at the heart of modern innovation, combining the principles of physics, chemistry, and engineering to unlock the secrets of materials and their properties. Materials scientists and engineers dedicate their work to researching, discovering, and developing new materials that can transform industries ranging from aerospace to energy. By studying the structure and behavior of materials at the atomic and molecular levels, they can design solutions that meet the ever-evolving needs of technology and society.

The field has advanced rapidly, especially with the rise of computational materials science. Researchers now utilize powerful computational tools to simulate and predict the performance of new materials, enabling them to optimize properties before a single sample is created. This approach accelerates the development of materials with tailored characteristics for specific engineering applications. Whether it’s creating lighter components for aircraft, more efficient solar panels, or stronger building materials, materials science is the driving force behind many of the world’s most important technological breakthroughs.

The Transistor: Foundation of Modern Electronics

Inventors: John Bardeen, Walter Brattain, and William Shockley (Bell Labs)

Year: 1947-1948

A transistor is a semiconductor device used to amplify or switch electronic signals and electrical power. It is made from materials like silicon or germanium and contains three primary layers, known as the emitter, base, and collector. By controlling the flow of current or voltage through these layers, a transistor operates as a fundamental building block for circuits, enabling complex functionalities in devices ranging from radios to computers.

The transistor patent fundamentally changed how we process information. Before this breakthrough, electronic devices relied on bulky vacuum tubes that consumed enormous amounts of power and generated excessive heat. The transistor provided a compact and efficient alternative that could amplify electrical signals or switch them on and off.

This innovation in materials engineering involved creating precise semiconductor junctions using germanium and silicon. The team at Bell Labs discovered how to control electrical conductivity by introducing specific impurities into these materials—a process called doping. This precise manipulation of material properties at the atomic level opened entirely new possibilities for electronic devices.

Nylon: The Synthetic Revolution

Inventor: Wallace Carothers (DuPont)

Year: 1935

Carothers’ nylon patent introduced the world to truly synthetic polymers. Unlike previous materials that modified natural substances, nylon was created entirely through chemical synthesis. This breakthrough demonstrated that materials scientists could design molecules with specific properties rather than simply adapting existing natural materials.

The invention process involved creating long chains of repeating molecular units known as polymers. Carothers discovered how to link these chains in ways that produced strong, flexible fibers. The resulting material exhibited remarkable tensile strength while remaining lightweight and resistant to many chemicals.

Nylon’s impact transformed multiple industries simultaneously. Textiles gained a durable, versatile fiber that could be manufactured consistently. Examples of nylon’s use include its application in textiles for clothing and parachutes, automotive parts such as gears and bearings, and in mechanical engineering components that require high wear resistance.

Kevlar: Bulletproof Innovation

Inventor: Stephanie Kwolek (DuPont)

Year: 1965

Kwolek’s Kevlar patent emerged from research into lightweight, strong fibers for tire reinforcement. Her breakthrough came when she chose to work with a polymer solution that other researchers had discarded as unusable. This decision led to the creation of liquid crystalline polymers with extraordinary strength-to-weight ratios.

The key innovation involved understanding how polymer chains could align in highly ordered structures. Kwolek discovered that under specific conditions, these chains would form rigid, rod-like arrangements that distributed stress exceptionally well. This molecular organization gave Kevlar its remarkable ability to absorb impact energy.

The applications extended far beyond the original tire research. Law enforcement gained lightweight body armor that could stop bullets. Aerospace engineers incorporated Kevlar into aircraft components. The material’s unique combination of strength, flexibility, and chemical resistance made it invaluable for protective equipment, sports gear, and industrial applications where traditional materials proved inadequate. Kevlar has played a critical role in advancing safety and innovation across multiple industries, establishing new standards for performance and protection.

Integrated Circuit: Miniaturization Breakthrough

Inventor: Jack Kilby (Texas Instruments)

Year: 1958

Kilby’s integrated circuit patent solved a critical problem in electronics: how to connect multiple components reliably while reducing size and cost. His solution involved creating all circuit elements—transistors, resistors, and capacitors—on a single piece of semiconductor material. Integrated circuits are a major achievement in condensed matter physics and materials science, representing the intersection of physics, engineering, and the study of complex materials.

This breakthrough enabled the computer revolution. Modern processors contain billions of components packed into spaces smaller than a fingernail. Medical devices became portable and sophisticated. The automotive industry integrated electronic controls throughout vehicles. Without this patent’s approach to materials miniaturization, smartphones, laptops, and countless other devices would remain impossible to create.

Teflon: The Non-Stick Wonder

Inventor: Roy Plunkett (DuPont)

Year: 1938

Plunkett’s Teflon patent originated from an accidental discovery during research on refrigerants. When a cylinder of tetrafluoroethylene gas polymerized unexpectedly, it created a waxy white substance with extraordinary properties. This material repelled virtually everything and remained stable at extreme temperatures.

The chemical structure of Teflon involves carbon atoms surrounded by fluorine atoms. This arrangement creates one of the most chemically inert substances known. Teflon’s unique chemical properties, particularly its resistance to chemical reactions and degradation, are critical for its use in demanding industrial applications. The strong carbon-fluorine bonds resist attack from acids, bases, and most other chemicals. Additionally, the smooth molecular surface provides minimal friction.

Teflon’s applications span numerous industries. Cookware manufacturers created non-stick surfaces that revolutionized food preparation. Chemical processing equipment gained corrosion-resistant linings. Aerospace applications utilized Teflon’s stability in extreme environments. The material’s unique properties made it essential for situations where traditional materials would fail due to chemical attack or adhesion problems.

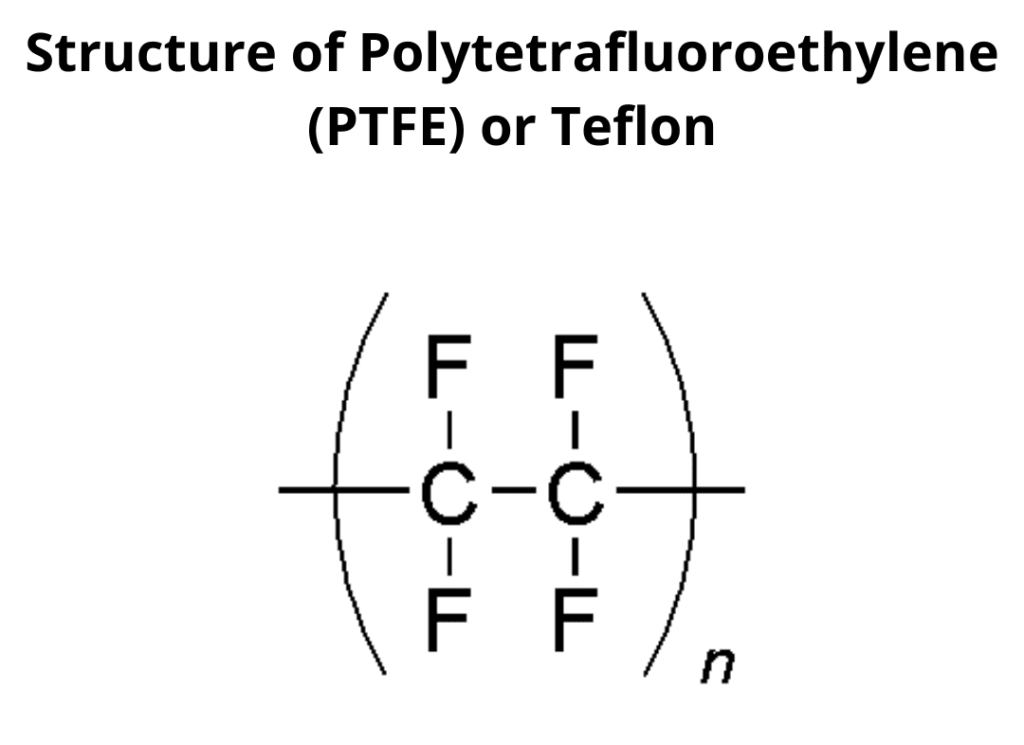

Carbon Fiber: Lightweight Strength

Inventor: Akio Shindo (Toray Industries)

Year: 1961

Shindo’s carbon fiber patent addressed the aerospace industry’s need for materials that combined exceptional strength with minimal weight. His process involved heating organic fibers in controlled atmospheres to remove non-carbon elements while preserving the fiber structure.

The manufacturing process requires precise temperature control and atmospheric composition. Organic precursor fibers undergo carbonization at temperatures exceeding 1000°C. This process removes hydrogen, oxygen, and nitrogen while leaving behind carbon atoms arranged in graphite-like structures. The resulting fibers exhibit strength comparable to that of steel while weighing significantly less.

Carbon fiber transformed multiple industries. Aircraft manufacturers reduced weight while maintaining structural integrity. Automotive engineers created lighter vehicles with improved fuel efficiency. Sports equipment manufacturers developed tennis rackets, golf clubs, and bicycles with enhanced performance characteristics. The material’s high strength-to-weight ratio made it indispensable for applications where traditional metals proved too heavy. Compared to alloys commonly used in aerospace and automotive industries, carbon fiber offers even greater weight savings and performance benefits, making it a preferred choice for high-performance applications. The development of carbon fiber has also inspired ongoing efforts to improve materials, driving innovation in creating lighter, stronger, and more efficient solutions for demanding technological needs.

Lithium-Ion Battery: Portable Power Revolution

Inventors: John Goodenough, Akira Yoshino, and Stanley Whittingham

Year: 1980s

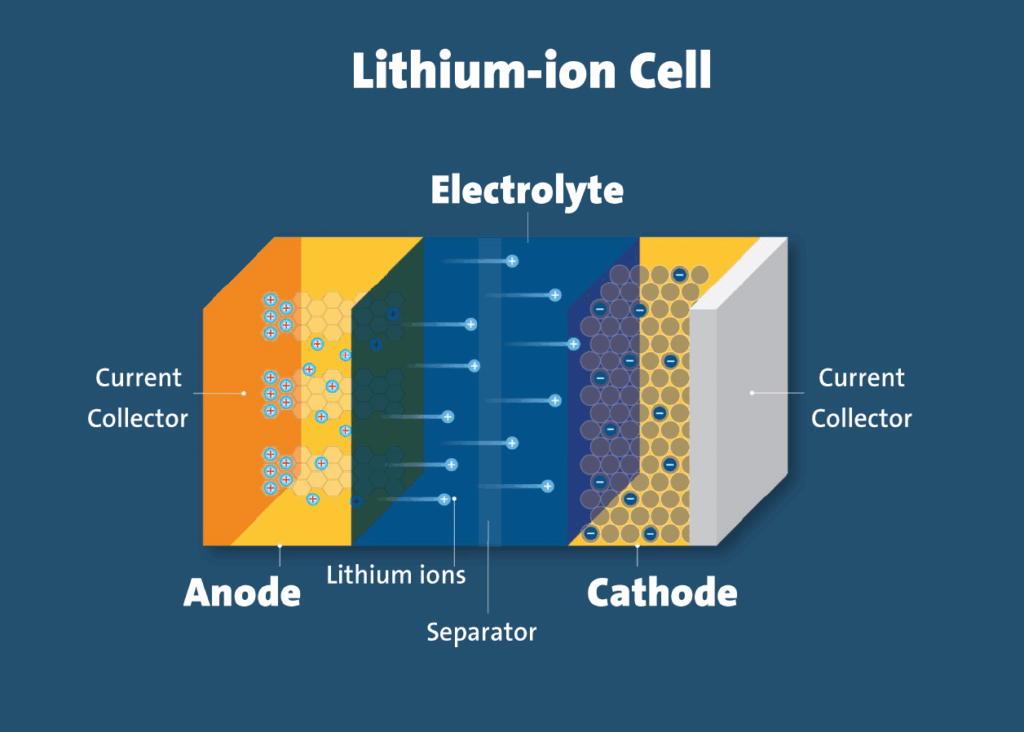

The lithium-ion battery patent represented a convergence of breakthroughs in materials science. The inventors needed to create materials that could repeatedly store and release lithium ions while maintaining their structural integrity. This required understanding how ions move through solid materials and designing electrodes that could accommodate this movement.

Smartphones, laptops, and tablets became practical due to the availability of reliable, rechargeable lithium-ion battery power sources. Electric vehicles gained feasible energy storage systems. Medical devices could operate cordlessly for extended periods. The ability to store electrical energy efficiently in compact packages transformed how we interact with technology. Lithium-ion batteries have enabled the development of innovative new products in electronics and transportation, driving advancements across multiple industries.

Optical Fiber: Information Superhighway

Inventors: Charles Kao and George Hockham

Year: 1966

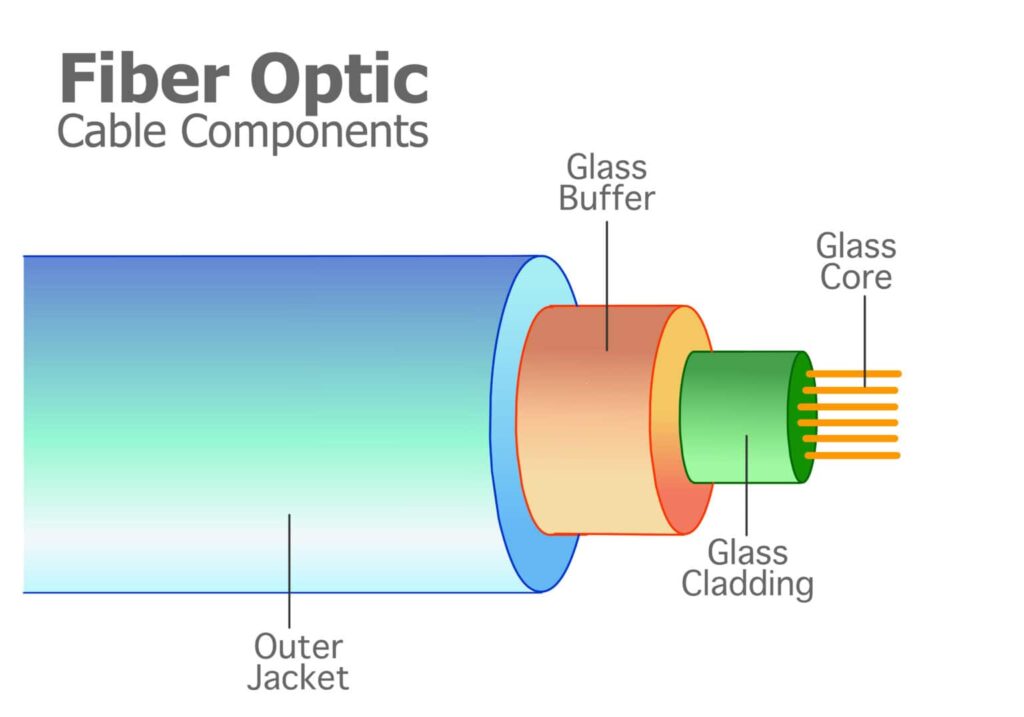

Kao and Hockham’s optical fiber patent solved the problem of long-distance communication with minimal signal loss. Their breakthrough involved creating ultra-pure glass that could transmit light signals over great distances without significant attenuation. Glass is a type of ceramic, and the development of optical fiber technology highlights the critical role of ceramics in enabling efficient, high-performance light transmission for communications.

The materials challenge required removing impurities that absorb or scatter light. The inventors developed manufacturing processes that produced glass with fewer than one part per billion of certain contaminants. The unique material properties of ceramics, such as their optical clarity and structural stability, were essential for achieving efficient light transmission in optical fibers. This purity level was unprecedented and required new approaches to materials purification and quality control.

Optical fiber enabled global communications. Internet infrastructure relies on fiber optic cables that span continents. Medical devices use fiber optics for minimally invasive procedures. Industrial sensors monitor conditions in harsh environments where electrical connections would fail. The ability to transmit information at the speed of light through carefully engineered materials has revolutionized how we share knowledge and conduct business.

Memory Foam: Comfort Through Chemistry

Inventor: Charles Yost (NASA)

Year: 1966

Yost’s memory foam patent emerged from NASA’s need for improved crash protection and comfort in spacecraft. The material needed to absorb impact energy while slowly returning to its original shape. This required understanding how polymer chemistry could create materials with specific mechanical properties.

The key innovation involved creating polyurethane foam with viscoelastic properties. This material responds to pressure and heat by conforming to applied forces and then slowly recovering its original shape when pressure is removed. The chemical structure includes cross-linked polymers that provide both flexibility and structural memory.

Understanding biology, particularly how materials interact with the human body, has informed the design of memory foam for medical and health-related applications. Consumer products, such as mattresses and pillows, utilized the material’s ability to conform to body shapes. Industrial applications included vibration damping and protective packaging. The patent demonstrated how materials designed for specific technical requirements could be applied to a wide range of commercial applications.

Aerogel: Solid Smoke

Inventor: Samuel Kistler

Year: 1931

Kistler’s aerogel patent addressed the challenge of creating solid materials with extremely low density. His process involved removing liquid from gels while preserving the solid network structure. This required understanding how to maintain structural integrity while removing most of the material’s mass.

The manufacturing process involves supercritical drying, which avoids the surface tension forces that would normally collapse the gel structure. The resulting material consists of up to 99% air trapped within a silica network. This creates exceptional insulation properties while maintaining structural stability.

Aerogel found applications in extreme environments. Space missions utilized its insulation properties for protecting sensitive equipment. Industrial processes benefited from its ability to provide thermal insulation in minimal space. Research applications included particle physics experiments where minimal material interference was crucial. Aerogel’s unique nanostructure places it among advanced nanomaterials, which are valued for their distinctive optical, electronic, and mechanical properties. Collaborative research and development projects played a significant role in advancing aerogel technology and expanding its applications. The patent’s approach to creating ultra-low-density materials opened new possibilities for thermal management and lightweight construction.

Impact on Other Fields

The influence of materials science and engineering extends far beyond traditional manufacturing and mechanical engineering. In medicine, the development of new materials has revolutionized medical devices, enabling the creation of advanced implants, prosthetics, and diagnostic tools that improve patient outcomes. Materials science also plays a pivotal role in energy, driving the development of more efficient batteries, solar cells, and fuel cells that support the transition to sustainable energy sources.

In the construction industry, materials scientists and engineers have developed innovative solutions such as green concrete and advanced composites, which enhance the durability and sustainability of buildings and infrastructure. These advancements not only enhance performance but also reduce environmental impacts, supporting the global effort toward for more sustainable development.

The integrative nature of materials science brings together chemists, physicists, biologists, and engineers to tackle complex challenges. By collaborating across disciplines, they can develop materials and technologies that address the needs of medicine, energy, construction, and beyond—demonstrating the broad and transformative impact of materials science and engineering on our world.

Materials Science: Shaping Tomorrow’s World

These ten patents represent more than individual innovations—they demonstrate the transformative power of materials science. Each breakthrough required a deep understanding of how atoms and molecules interact to create useful properties. The inventors didn’t just discover new materials; they created entirely new categories of functionality.

The impact extends across every aspect of modern life. Our communication systems rely on optical fibers and semiconductors. Materials science innovations also play a crucial role in reducing environmental impact and supporting sustainability.

Looking to Protect Your Intellectual Property?

Please contact Arlen Olsen at Schmeiser, Olsen & Watts LLP at aolsen@iplawusa.com.

About the Author

Mr. Olsen, a former adjunct professor of intellectual property law, has over 30 years of experience in all aspects of intellectual property law. Mr. Olsen is a founding Partner of Schmeiser, Olsen & Watts LLP and a former United States Patent Examiner. Mr. Olsen has prosecuted numerous patents that have been litigated and received damages of over 60 million dollars. Additional activities include teaching seminars, appearing as a guest lecturer on intellectual property matters for corporations and educational institutions, and evaluating and consulting with clients regarding the scope, enforcement, and protection of intellectual property rights.